"Dedicated to the preservation and enjoyment of skiing with wooden skis"

Rottefella Ski Binding History

|

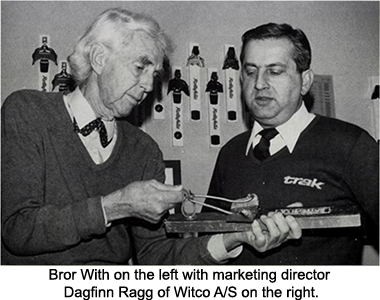

According to With's personal notes, the patent for the Huitfeld binding had expired and the newspapers were full of proposals for new bindings. Bror With thought that he could come up with a different binding for the race at Lysaker. He tore out the post on a bicycle seat and forged it into a clamp. Then he installed some spikes into a couple of pieces of steel Marius Eriksen toe irons and drilled holes in the ears for the clamp. When With arrived at the start of the ski race, he met an interested Crown Prince Olav who asked what kind of ski binding he had. Bror reacted quickly and answered with excitement, "these are only a couple of Rat Traps (Rottefella) I bought from Ingwald Nilsen". During the race he noticed that the bindings held fast during the toughest descents, so the idea to start production was initiated then and there. At the finish of the race, he was met with exclamations that what he had said to the Crown Prince was funny and that he should patent the name "Rottefella", as well as the bindings. Production of Rottefella bindings was started soon after that.

Several improvements made the binding more stable and durable. Johannes Trageton from Geilo was annoyed that the leather strap which connected the hoop to the ski base often broke. It also did not work well with ice on it and on soft trails. Johannes got an idea for an adjustable hook device with five notches, and started working on it in his shop. The hook worked well and it was patented. Gresvig bought the invention for 150 kroner and sold it to the manufacturer of Rottefella. Industrial production of Rottefella bindings started in the late 1930s, and continuous improvements occured. When Rottefella started with aluminum in the bindings in the 1960s, it became easier to use different colors. A separate company, Witco, was established in Oslo in 1973. Dozens of binding manufacturers at home and abroad took part in a growing market. Adidas launched big news with a toe binding during the 1976 Olympics, made known by the Soviet Yevgeny Beljaev who lost a ski in the relay because the binding did not hold.

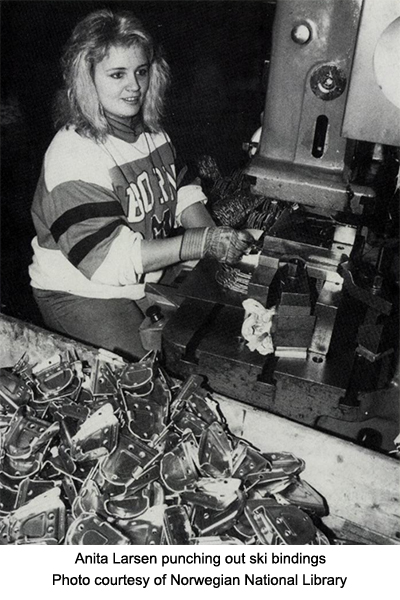

Rottefella continued to launch important innovations for versatile ski use: skating, Telemark and touring - and a third generation NNN in 1999. Rottefella's strength is innovation and advanced technology. Master of Science in Engineering and Inventor Bernt Otto Hauglin (1940–) has represented both innovation and continuity since in the early 1970s. Together with the company's development team and test skiers in many countries, he works diligently on improvements. Why have they not flamed out like many other Norwegian companies? There are obvious benefits of being in Norway; everything can happen faster and the distances are negligible. Developers work a few steps away from the factory, and Rottefella built a new plastic factory in Hurum. About. 60 of the company's 70 employees in 2007 worked in production. It is time consuming hand work to make bindings. A racing binding for cross-country skiing consists of 15 parts as made by hand, the telemark binding requires up to 80 operations. The workers are working in small teams in bright premises, with a short distance to bosses and offices. In the course of a day, 300,000 parts pass through the factory.* |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

|  |

Back to Home

Sources: * Skimakerne, Thor Gotaas, 1997 - Norwegian National Library - Rottefella website

© Copyright 2021, Greg Fangel, www.woodenskis.com

In the winter of 1927, Norwegian inventor and mechanical engineer Bror With (1900–1986) looked forward to a ski race from Lysaker to Sørkedalen. In the days before the race, he thought about improvements, which could be made to

In the winter of 1927, Norwegian inventor and mechanical engineer Bror With (1900–1986) looked forward to a ski race from Lysaker to Sørkedalen. In the days before the race, he thought about improvements, which could be made to  A blacksmith at Rodeløkka did the hard work, and Einar Piene, who ran

A blacksmith at Rodeløkka did the hard work, and Einar Piene, who ran  In conjunction with increasing sales of cross-country skis in the world, Rottefella reached a peak in 1979–1980 with production of 1.6 million bindings. New Nordic Norm (NNN) in 1985 meant a lot to Rottefella. It was important to the main competitor, French Salomon, which had over half the market for cross-country bindings in Norway. The French copied Rottefella, who responded four years later with NNN II. In the 1980s, the Møller group acquired Witco, and in 1985 the company merged with Røyken hardware factory, which also made ski bindings. Production was moved to Hurum, and in 1991, the company name was changed to Rottefella AS.

In conjunction with increasing sales of cross-country skis in the world, Rottefella reached a peak in 1979–1980 with production of 1.6 million bindings. New Nordic Norm (NNN) in 1985 meant a lot to Rottefella. It was important to the main competitor, French Salomon, which had over half the market for cross-country bindings in Norway. The French copied Rottefella, who responded four years later with NNN II. In the 1980s, the Møller group acquired Witco, and in 1985 the company merged with Røyken hardware factory, which also made ski bindings. Production was moved to Hurum, and in 1991, the company name was changed to Rottefella AS.